3, Functional description of each part:

1. Traction Department:

1. The traction roller is driven by a 3.7KW servo motor.

2. Waste edge recycling device:

Use a fan to blow out the waste and waste materials, and the

customer will equip a mesh box for collection.

3. Winding mechanism: (The left or right end of the finished

product is determined by the customer when placing an order)

1. The cut material is independently wound using both upper and

lower axes, and the slitting knife uses a straight knife for

slitting (6 pairs)

2. The upper and lower winding shafts each have one 3.7KW servo

motor with pneumatic expansion shaft. The winding tension is

automatically controlled by Siemens PLC based on the current coil

diameter, ensuring that the finished material is neat when multiple

slits are cut. All coil end faces are flat, and the flatness of the

disc surface is freely selected by the pneumatic pressure roller

and the self weight pressure roller for cutting. The tightness of

the inner and outer layers of the finished coil is controllable,

which is a spiral winding method. As the winding diameter continues

to increase, Siemens PLC automatically controls the speed of the

winding servo motor to decrease.

5. Discharge device

Adopting a connected shaftless hydraulic automatic feeding

structure

(1) 1 set of analog correction motor

(2) Guide rail 25 model 4 pieces

(3) One pair of high-quality steel is used for the 40 thick

memorial archway

(4) 1 pair of lifting swing arms

(5) Cylinder 140X63 1 pair

(6) The discharge brake adopts one pair of air brakes

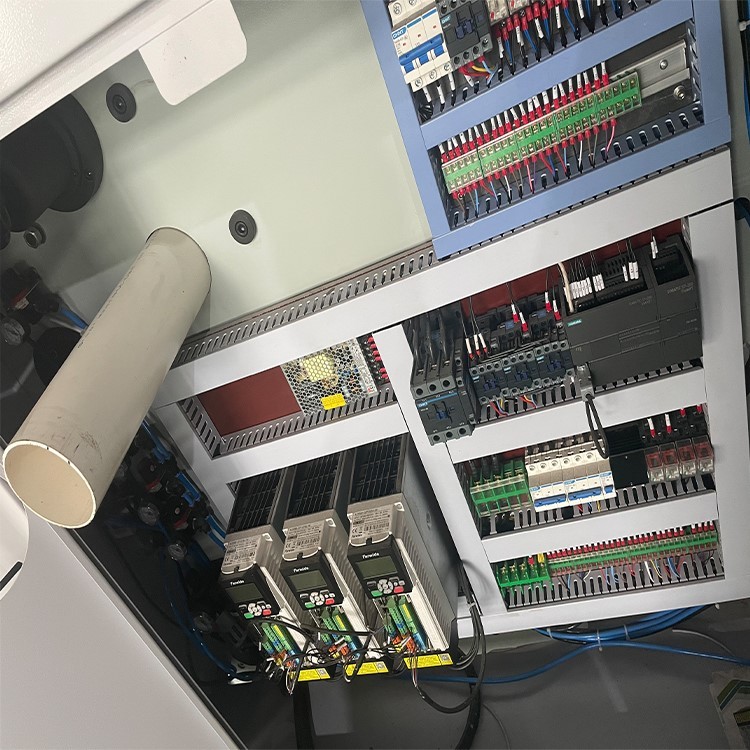

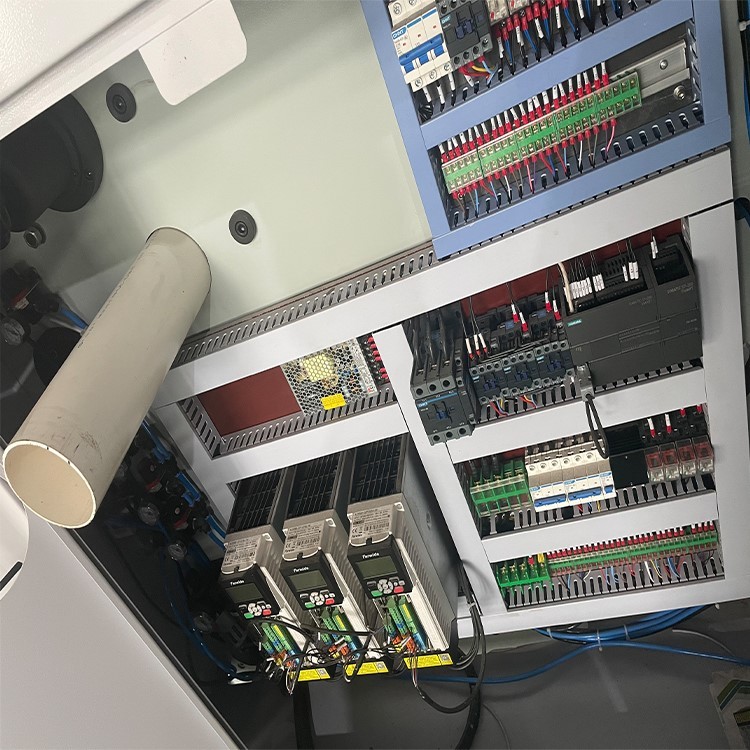

Electrical equipment adopts

Chint Group is used for low-voltage electrical appliances, Snyder

is used for button switches, Siemens is used for PLC, and the

operating system of the whole machine is controlled

The tension of the winding air pressure is controlled by Siemens

PLC, and the tension is controlled by an electric proportional

valve

control section PLC adopts Siemens The electrical equipment adopts

Chint

drive control Using three Shenzhen Hongyuan drives

Distribution box section

Correction system

Simulated correction using bats

Operation section

The touch screen adopts Kunlun connected 7-inch mode

The switch adopts Snyder

The air pressure regulation is controlled by a precision regulating

valve

5.

Delivery cycle: within 35 working days.

Company name: Haijing Machinery

Person in charge: Manager Wu

Phone number: 1381975362918627295765