1, Parameter indicators:

1. Material type: roll like materials such as self-adhesive, paper,

non-woven fabric, printing composite, etc;

2. Material thickness; 30-450g (paper)

3. Maximum width of raw materials: 1300mm

4. Roll surface width: 1350mm

5. Cutting width: 15-1300mm

6. Reeling tube core: 3 "paper tube; using 2 Duluo gas expansion

shafts

7. Maximum diameter of winding: 1000mm

8. Maximum speed: 600 meters/minute

9. Cutting speed: 10-600 meters/minute

10. Total power supply: 25KW

11. Total weight: approximately 5400KG

12. External dimensions: 3600 in length, 2650 in width, and 1950mm

in height

| Part Name | Specification and model | quantity | brand |

| 45 # steel frame | Wall panel net thickness 40mm | 1 pair | |

| 3-inch inflatable shaft | Plating Luo | 2 pieces | |

| Main traction roller steel rod plating | φ 200 * 1350mm | 1 piece | |

| Main traction rubber roller polyurethane | φ 180 * 1350mm | 1 piece | |

| Hard alumina guide roller | Φ 125 * 1350mm | 10 pieces | |

| Winding servo | 7.5KW | 2 sets | Beauty Department |

| Traction servo | 7.5KW | 1 set | Beauty Department |

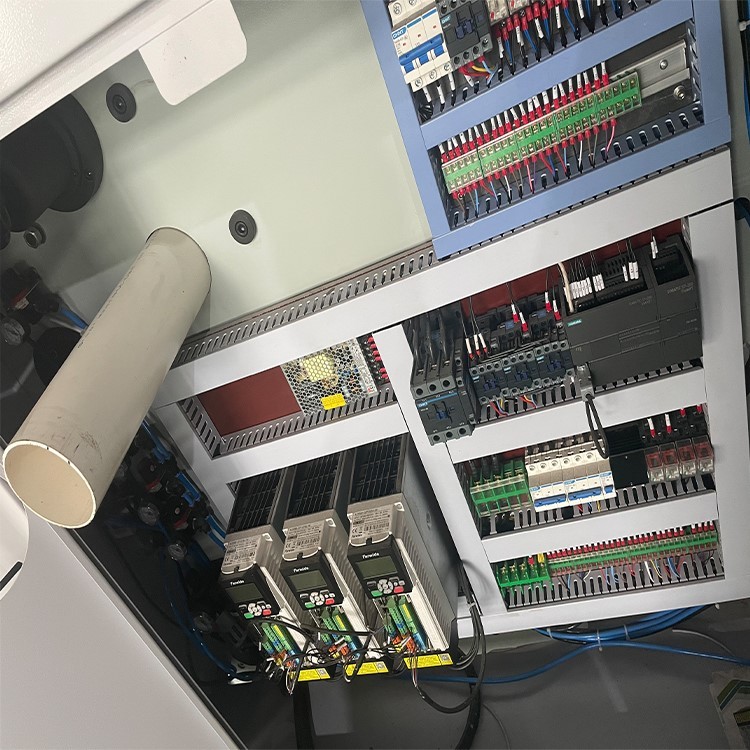

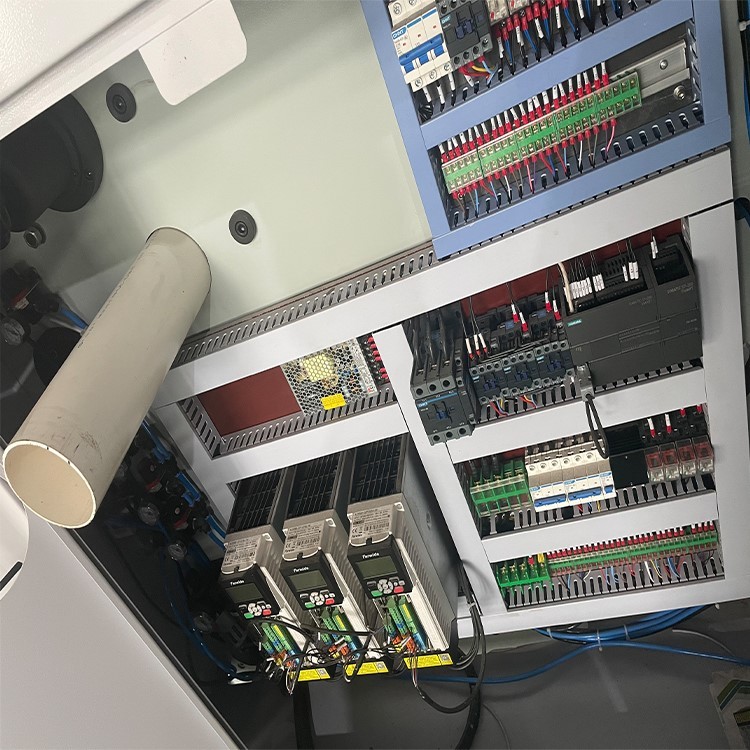

| drive | 7.5KW | 3 units | |

| Waste blowing edge fan | 1.5KW | 1 unit | Wuxi |

| bearing | | 1 batch | HRB |

| pneumatic components | | 1 batch | |

| Circular knife adopts | | 8 units | Shenzhen Hongyuan |

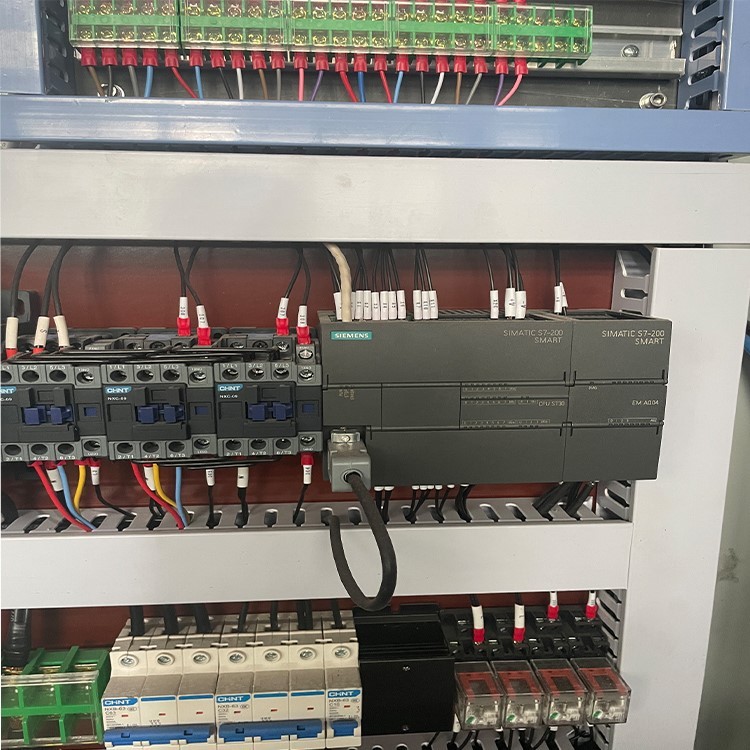

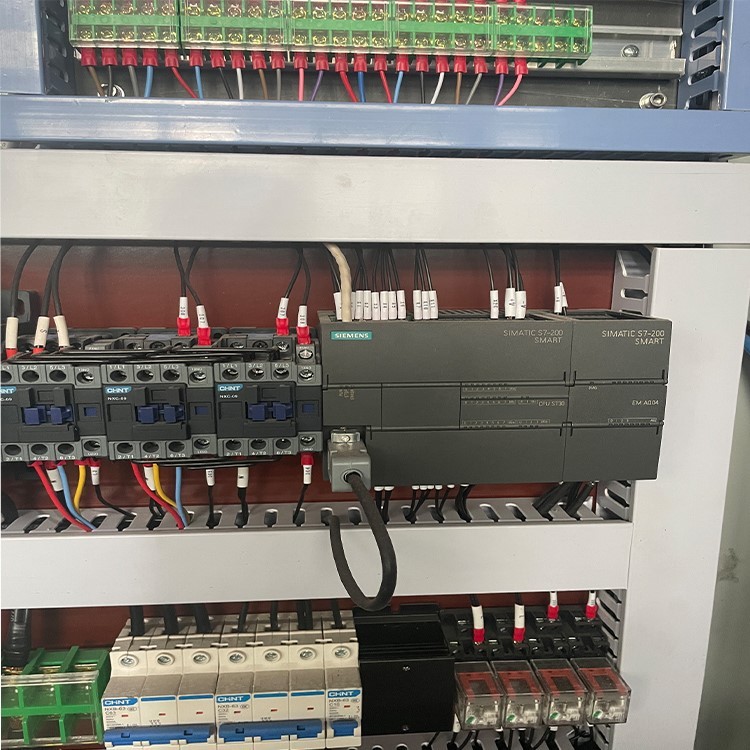

| Master PLC programmable controller | CPU224XP | 1 piece | Siemens |

| 10-inch true color touch screen | TPC1061Ti | 1 piece | Beijing Kunlun Tongshi |

| proximity switch | | 1 piece | Japan OMRON |

| Low Voltage Apparatus | | 1 batch | schneider |

| switch power supply | S100-24 | 1 piece | mean well |

3, Functional description of each part:

1. Traction Department:

1. The traction roller is driven by a 7.5KW servo motor.

2. Waste edge recycling device:

Use a fan to blow out the waste and waste materials, and the

customer will equip a mesh box for collection.

III. Winding mechanism: (finished product unloading is completed

mechanically)

1. The cut material is independently wound using both upper and

lower axes, and the slitting knife uses a circular knife for

slitting (8 pairs)

2. The upper and lower winding shafts each have one 7.5KW servo

motor with pneumatic expansion shaft. The winding tension is

automatically controlled by Siemens PLC based on the current coil

diameter, ensuring that the finished material is neat when multiple

slits are cut. All coil end faces are flat, and the flatness of the

disc surface is freely selected by the pneumatic pressure roller

and the self weight pressure roller for cutting. The tightness of

the inner and outer layers of the finished coil is controllable,

which is a spiral winding method. As the winding diameter continues

to increase, the PLC automatically controls the speed of the

winding servo motor to decrease.

5. Discharge device

Adopting a shaftless hydraulic automatic feeding structure

(1) One pair of discharge chassis

(2) 1 set of analog correction motor

(3) Guide rail 35 model 8 pieces

(4) One pair of high-quality steel is used for the 40 thick

memorial archway

(5) 1 pair of lifting swing arms

(6) Cylinder 4 pairs

(7) 1 pair of non axis top cones

(8) Air brake 1 pair

Electrical equipment adopts

Chint Group is used for low-voltage electrical appliances, Snyder

is used for button switches, Siemens is used for PLC, and the

operating system of the whole machine is controlled

4, Machine Part Location

Overall appearance

Upper and lower center winding diameter 1000mm

Hydraulic shaftless automatic lifting, labor-saving material

placement, and simple operation

High quality sensors align the fabric and make the material flat

Circular knife device, or air knife device, optional

Tension control function

Servo motor device function

Main connected distribution box

Unloading using a reducer

Drive adopts Hongyuan

PLC adopts Siemens from Germany

Automatic meter counting, alarm parking, automatic control and

other functions

10 inch touch screen, Kunlun connected state

Company name: Haijing Machinery

Person in charge: Manager Wu

Phone number: 13819753629,18627295765