3, Functional description of each part:

1. Unwinding Department:

1. The unwinding adopts a shaftless pneumatic feeding rack, which

is convenient for single person operation. Adopting a special

inflatable shaft form, it does not damage the inner wall of the

tube core.

2. There are three modes for freely switching the unwinding

tension: pressure sensor closed-loop automatic constant tension

control mode, pressure sensor free open-loop automatic constant

tension control mode, and manual tension.

3. The unwinding diameter is automatically detected by the

proximity switch at the unwinding transmission shaft, without the

need to input material thickness. The residual unwinding diameter

can be set to automatically slow down and stop, making it

convenient for the next coil to be received.

4. Equipped with a mechanism for manually adjusting the release and

tightening edges, with an adjustment range of ± 10mm.

5. The automatic deviation correction system automatically corrects

the edge of the film or paper.

II. Traction Department:

1. The traction roller is driven by a 5.5KW servo motor.

III. Waste edge recycling device:

Use a fan to blow out the waste and waste materials, and the

customer will equip a mesh box for collection.

4. Winding mechanism: (The left or right end discharge of finished

products is determined by the customer when ordering)

1. Use both upper and lower axes to independently roll the cut

material.

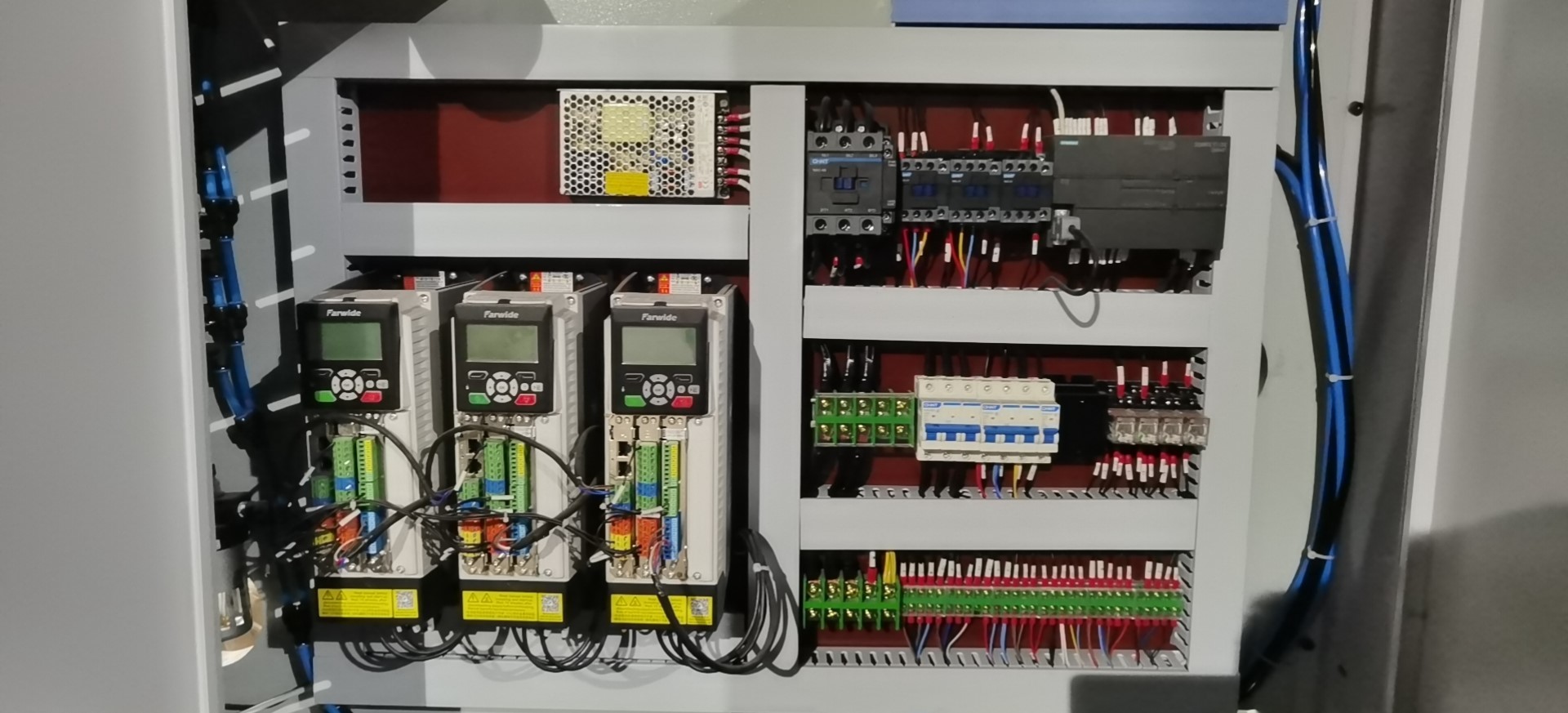

2. There is one 5.5KW servo motor with pneumatic expansion shaft

for the upper and lower winding shafts. The winding tension is

automatically controlled by PLC based on the current coil diameter,

so that there is no material thickness factor when multiple slits

are cut. All coil end faces are flat, and the flatness of the disc

surface is freely selected by the pneumatic pressure roller and the

self weight pressure roller for cutting. The tightness of the inner

and outer layers of the finished coil is controllable, which is a

spiral winding method. As the winding diameter continues to

increase, the PLC automatically controls the speed of the winding

servo motor to decrease.

6. The slitting knife adopts a round knife for slitting (6 pairs),

with an optional air knife (320 yuan per piece)